Resources and Mining Industry

Construction Specialists

Sun Engineering, with over 40 years of experience since the 1970s, specializes in fabrication, SMP construction, and commissioning of processing & bulk handling systems for various materials like Gold, Coal, Wood chip, and Cement. Our capabilities include process systems, gravity circuits, thickeners, paste backfill plants, storage facilities, Stacker’s, reclaimers, stockyards, wharves, wharf conveyors, conventional and suspended conveyor systems (long span aerial systems), and pipe conveyors. With extensive industry experience, we deliver cost-effective solutions while adding value to our clients’ projects.

Our mission is to adapt to your project needs and ensure minimal interruption to your operations during project execution. With a dedicated and experienced team, we prioritize safety, quality, and timely delivery, exceeding expectations.

Gold

Sun Engineering, with over 40 years of experience since the 1970s, specializes in fabrication, SMP construction, and commissioning of processing & bulk handling systems for various materials like Gold, Coal, Wood chip, and Cement. Our capabilities include process systems, gravity circuits, thickeners, paste backfill plants, storage facilities, Stacker’s, reclaimers, stockyards, wharves, wharf conveyors, conventional and suspended conveyor systems (long span aerial systems), and pipe conveyors. With extensive industry experience, we deliver cost-effective solutions while adding value to our clients’ projects.

Our mission is to adapt to your project needs and ensure minimal interruption to your operations during project execution. With a dedicated and experienced team, we prioritize safety, quality, and timely delivery, exceeding expectations.

Coal

Since the 1980s, Sun Engineering has been highly regarded for its expertise in delivering and expanding coal terminals on Australia’s east coast. In our Brisbane workshop, we manufacture transfer towers, conveyors, ROM bins, surge bins, and dump stations. Our SMP construction division installs and commissions various coal-related projects, including Coal Rail Dump stations, 6km overland conveyors, wash plants, stockpiles, ship loading expansions, and control rooms. Our satisfied clients include RG Tanner, North QLD Bulk Ports, Gladstone Ports Authority, WICET, and BHP.

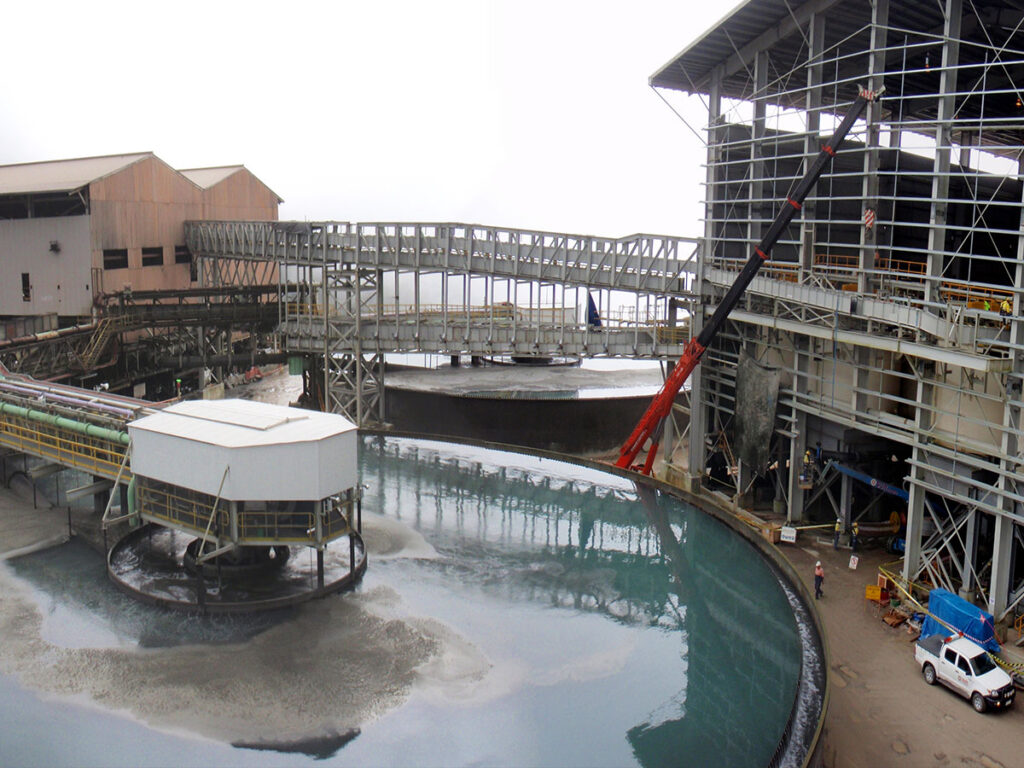

Mineral Sands

In the late 1990s, Sun Engineering achieved a successful relocation and upgrade of a sand mine process facility, including a dredge, pipework, and the world’s largest floating thickener in Queensland. Since then, we have provided support for multiple mineral sands projects by offering offsite fabrication and assembly of pipework, platework, and steel refurbishment for skid-mounted designs. Additionally, we have undertaken the refurbishment and recommissioning of sunken concentrator pontoons, including 6 x Spiral module and 9 x surge bin modules.

Steel Fabrication & Construction

For Resource Mining Industries

Sun Engineering offers EPC (Engineer-Procure-Construct) Delivery, a comprehensive service that addresses all project stages, from design and engineering to construction and commissioning. Our approach is highly collaborative, as we tailor solutions to meet clients’ unique requirements, going beyond their expectations. With a focus on delivering on time and within budget, we prioritize quality and safety throughout the project. Rest assured that your project will be handled with the utmost professionalism, meeting your precise specifications and schedule.

We excel in steel fabrication, handling carbon, stainless, and aluminium materials. Our skilled engineers and fabricators use advanced equipment to craft precise, high-quality products tailored to your specifications. Whether it’s structural steel for buildings, custom-made steel products, or specialized equipment, we deliver top-notch results. Our commitment to innovation ensures that we meet project goals while upholding industry-leading safety and quality standards.

We provide custom pipe spooling services for the resource industry, employing precision engineering and advanced technology for top-quality and accurate outcomes. Our cost-effective solutions aim to minimize downtime, enhance efficiency, and optimize project performance. Count on us to meet your specific project needs with unmatched quality and service.

Our SMP (Structural Mechanical Piping) services offer a comprehensive solution for structural steel, mechanical equipment, and piping requirements in the resource industry. With a team of experienced engineers and fabricators, we collaborate closely with clients to deliver customized solutions that match their specific needs, ensuring top-notch quality and safety standards. From design and engineering to fabrication, installation, and maintenance, our end-to-end SMP services are tailored to meet the unique demands of our clients.

Our site welding services cater to the resource industry, delivering top-quality welding solutions tailored to meet specific client needs. Our team consists of experienced and certified welders equipped with state-of-the-art welding equipment and technology, ensuring projects adhere to the highest safety and quality standards. Our welding services cover a range of techniques, including MIG, TIG, Stick welding, and specialized methods.

We provide a variety of conveyor systems, such as belt conveyors, chain conveyors, screw conveyors, and more. Our team of experienced engineers and fabricators collaborates closely with clients to design and manufacture customized conveyor systems that precisely match their project requirements. Utilizing the latest technology and equipment, we ensure that every conveyor system we build is dependable, efficient, and cost-effective. Our end-to-end conveyor services cover installation, commissioning, ongoing maintenance, and repair, all geared towards helping clients achieve their project goals.

Our experienced team of engineers and fabricators specializes in API 650 tank design and construction for clients in the resource industry. Our comprehensive services cover tank design, fabrication, installation, and maintenance. We collaborate closely with clients to tailor each tank to their specific requirements and project objectives. With our expertise in API 650 tank design and construction, you can trust that your project will be completed punctually, within budget, and with the utmost emphasis on quality and safety.

Our shop-built tanks are crafted with the highest standards of quality and safety, providing clients in the resource industry with reliable and cost-effective solutions. We offer a diverse range of shop-built tanks, including carbon steel, stainless steel, and aluminium tanks, along with specialty tanks. Our services encompass design, engineering, fabrication, installation, and maintenance, ensuring end-to-end support tailored to the specific requirements of each client.

We collaborate closely with clients to design, engineer, and manufacture equipment customized to their specific needs and project objectives. With our experienced team of engineers and fabricators utilizing the latest technology, every piece of equipment we produce is precision-engineered and held to the highest quality and safety standards. Our OEM equipment offerings include crushers, screens, conveyors, and more. Whether it’s small parts or large equipment, our end-to-end OEM equipment manufacturing services are designed to support clients in achieving their project goals.

Our Greenfield/Brownfield project delivery services offer comprehensive solutions for project development in the resource industry, covering the entire lifecycle from concept to completion. Our team of project managers, engineers, and construction professionals collaborates closely with clients, guaranteeing timely delivery, budget adherence, and the highest standards of quality and safety. Our services span project planning, feasibility studies, construction, commissioning, and ongoing maintenance, providing end-to-end support tailored to the distinct needs of each project.

Our skid mounted assembly services provide tailored solutions for clients in the resource industry, focusing on mobility, ease of installation, and maintenance. We offer various skid mounted assemblies, including process modules, electrical rooms, and pump skids.

Working closely with clients, our experienced team of engineers and fabricators designs and manufactures skid mounted assemblies to match their specific project requirements. Utilizing the latest technology and equipment, we ensure each assembly is reliable, efficient, and cost-effective. From design and engineering to fabrication, installation, and maintenance, our end-to-end skid mounted assembly services are designed to support clients in achieving their project goals.